Magnetic Chip Conveyors: A Dependable Resolution for Environment friendly Metal Chip Management

Magnetic Chip Conveyors: A Dependable Resolution for Environment friendly Metal Chip Management

Blog Article

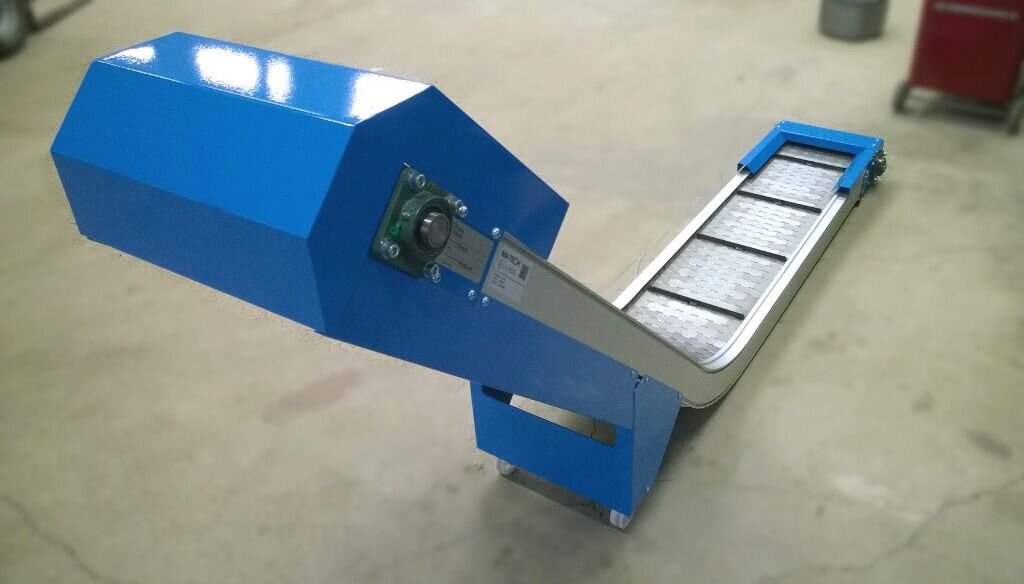

Magnetic chip conveyors are an essential tool for industries that deal with metalworking and machining processes, which often produce large amounts of metal chips, shavings, and other waste materials. The efficient removal and handling of metal chips is crucial in industries such as automotive manufacturing, aerospace and machining. These sharp, tiny, and sometimes tangled parts can be difficult to handle with traditional conveyor systems. Magnetic chip conveyors solve these challenges by using powerful magnets to attract and securely transport ferrous metal debris, ensuring a cleaner and safer working environment. By automating chip removal, these conveyors reduce material losses, eliminate manual handling and increase overall efficiency. They are indispensable for many industrial applications.

Magnetic chip conveyors are able to transport ferrous metals such as steel, iron and other magnets that are produced by machining. The sharp edges of these metals can make them difficult to handle, and they tend to pile up in conveyor systems or get tangled. Magnetic conveyors address this issue by using powerful magnets either embedded in the belt or placed beneath the surface of the conveyor. Magnets produce a magnetic force that holds ferrous material in place as it moves along a conveyor. The magnetic field prevents metal chips falling or being misaligned. This ensures that the chips are transported safely to the designated point. This method of handling metal chips reduces the need for manual labor, improves safety, and ensures a cleaner and more efficient work environment.

Magnetic chip conveyors are highly versatile and can be tailored to suit the needs of various industries. Magnetic conveyors are available with flat, inclined or curved belts, depending on the material to be handled and layout of the facility. This adaptability allows them to transport materials in various directions, whether horizontally, vertically, or at an angle, making them suitable for use in facilities with complex production workflows. Magnetic conveyors are also able to be customized for metal chips with different weights and sizes. The strength of the magnets can be adjusted depending on the size of the chips being transported, allowing businesses to choose the right level of magnetic force for their needs. Magnetic chip conveyors are highly customizable, allowing them to be used in a variety of manufacturing processes, from small workshop productions to large scale factories.

Magnetic chip conveyors can also increase operational efficiency, reducing maintenance and downtime costs. Traditional conveyor systems often rely on friction to move materials, which can lead to frequent wear and tear on belts and other components. This wear requires regular maintenance and can cause operational delays, leading to costly downtime. Magnetic Chip Conveyors, however, reduce friction because the magnets hold the material securely without direct contact between the conveyor belt and the chips. This not only increases the longevity of the conveyor system but also minimizes maintenance requirements, allowing businesses to save on repair costs and prevent disruptions to their production lines. In environments where continuous production is crucial, magnetic chip conveyors provide a more reliable, low-maintenance alternative to conventional systems. To acquire extra details kindly look at Tecnimetal

In addition to enhancing efficiency and reducing maintenance, magnetic chip conveyors improve safety within the workplace. Metal chips, particularly in industries like machining, can pose significant risks to workers if not properly handled. They can be dangerous, particularly if they are accumulated on the floor of the workshop or near machinery. Magnetic conveyors automate the chip removal process, reducing the amount of manual handling required by workers. It is also safer for workers to avoid exposure to metals waste. Furthermore, magnetic conveyors help maintain a cleaner and safer work environment by preventing chips from accumulating on the floor or around machinery, reducing the likelihood of slips, trips, or falls.

Magnetic chip conveyors are not only efficient and safe, but they also help to maintain the sustainability of an industrial operation. These conveyors ensure valuable materials do not go to waste by removing metal chip from production floors. The collected chips can often be recycled and reused, particularly in industries that rely on expensive materials like steel or titanium. Metal chips can be recycled to reduce material costs, and help companies minimize their impact on the environment by minimising waste. Furthermore, by automating the chip removal process, businesses reduce the need for manual labor, allowing workers to focus on more productive tasks. The increased efficiency reduces costs and contributes to environmentally-friendly business practices.